Hotline

Search:

From September 10 to 12, 2025, Royma Industrial CT showcased its new RMX8000 at the SEMI-e Shenzhen International Semiconductor Exhibition. The event, held in Shenzhen, brought together leading enterprises and professionals from across the global semiconductor industry chain. During the exhibition, representatives from the semiconductor industry associations of the Philippines, Malaysia, and Singapore visited Royma’s booth, engaging in in-depth discussions on semiconductor inspection technology, industry trends, and innovative applications.

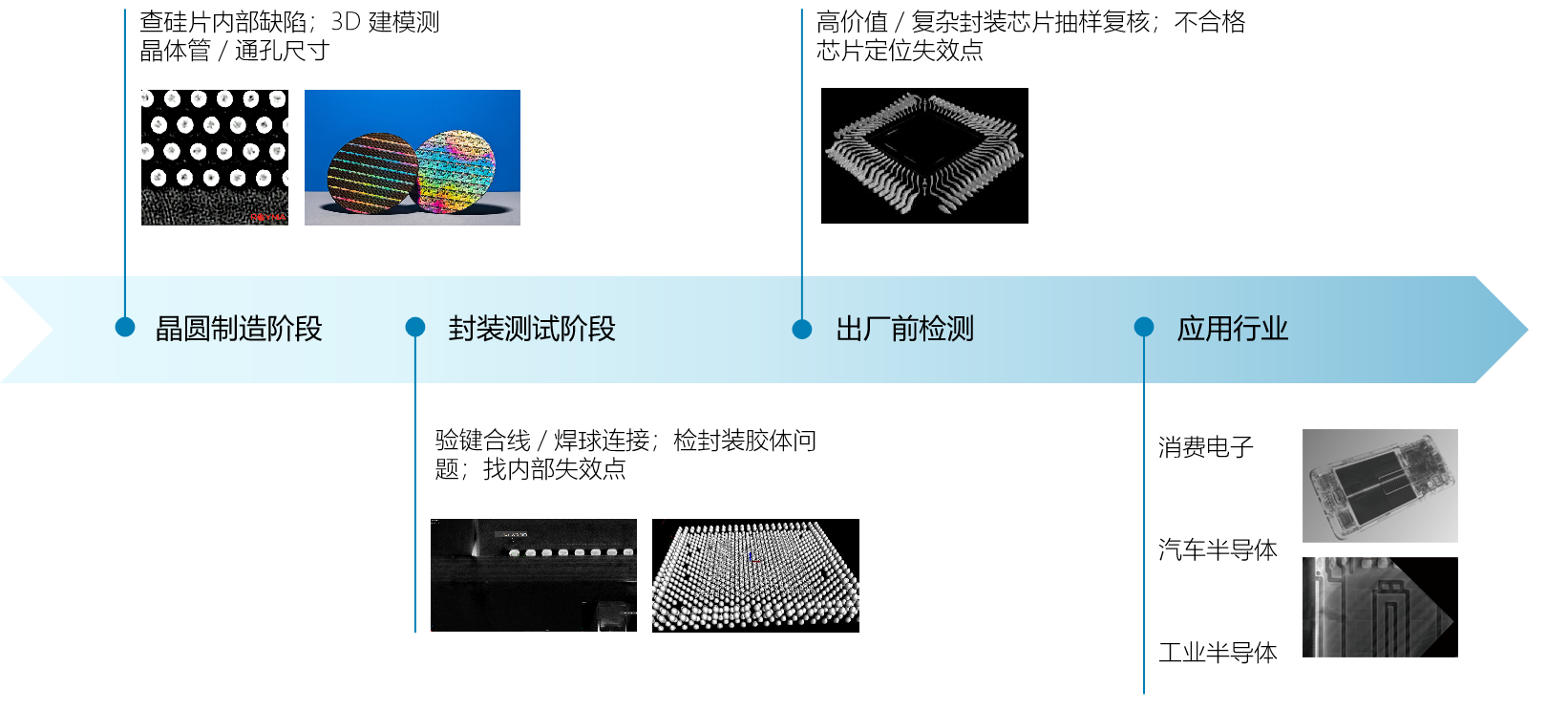

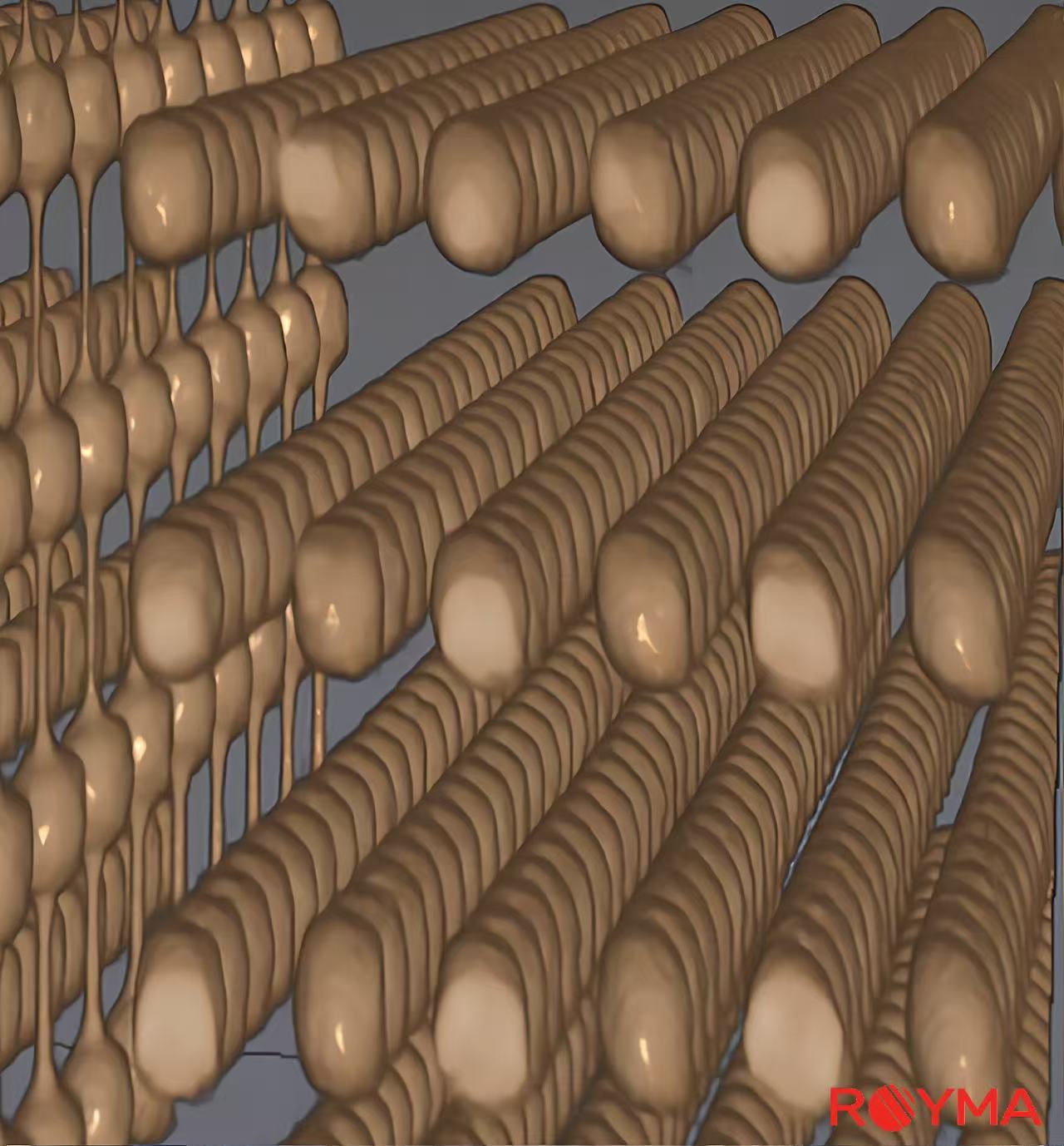

With its core strengths of “non-destructive penetration + 3D visualization,” Royma Industrial CT provides inspection support for the semiconductor front-end, mid-end, back-end, as well as multiple related industries, establishing itself as a key force in ensuring quality across the entire process—from materials to equipment, from manufacturing to applications.

RMX8000

Micro- and Nano-scale Inspection System

The RMX8000 is equipped with a high-resolution CMOS flat-panel detector and a 150nm transmission-target nano X-ray source, paired with a granite base and five-axis motion system for stable and reliable operation. It is primarily used for IC packaging (BGA), solder balls, and wafer defect inspection, supporting automatic loading/unloading mechanisms and customized AI recognition algorithms, significantly improving product inspection efficiency.

RMPCT5500

igh-Speed Inline Planar CT Inspection System

The RMPCT5500 features high penetration, high-precision measurement, and strong scalability. Equipped with both classic and innovative scanning modes, it is widely used for internal defect inspection of precision components in industries such as semiconductors, lithium batteries, automotive manufacturing, aerospace, and electronic devices.

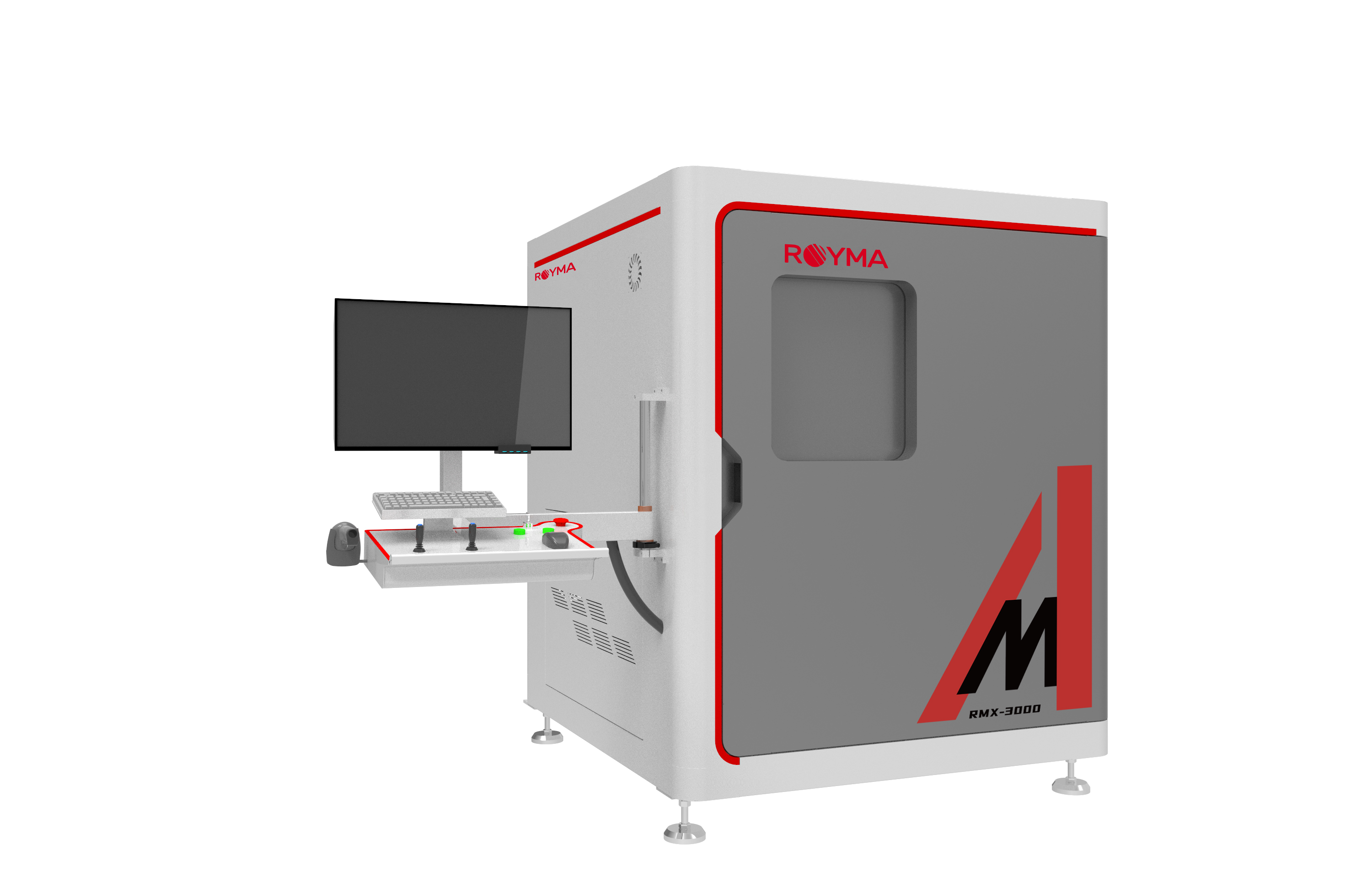

RMX3000

Offline X-Ray Inspection System

The RMX3000 features high-contrast imaging with excellent image consistency, equipped with an open X-ray tube and self-calibration function. Its five-axis motion platform supports full-range continuous observation, and ACT/PCT scanning modes are also available as optional configurations.

We sincerely thank all our new and returning friends for visiting Royma’s booth and engaging with us in discussions on innovations and applications of industrial CT in semiconductor inspection. Although the exhibition has concluded, the exchange of ideas and insights continues. We will carry forward the valuable feedback you shared and continue to deepen our work. We look forward to turning these discussions into future collaborations and moving forward together. Farewell!

Get in touch with us, our experts will help you